Cosmetics

3 minute read

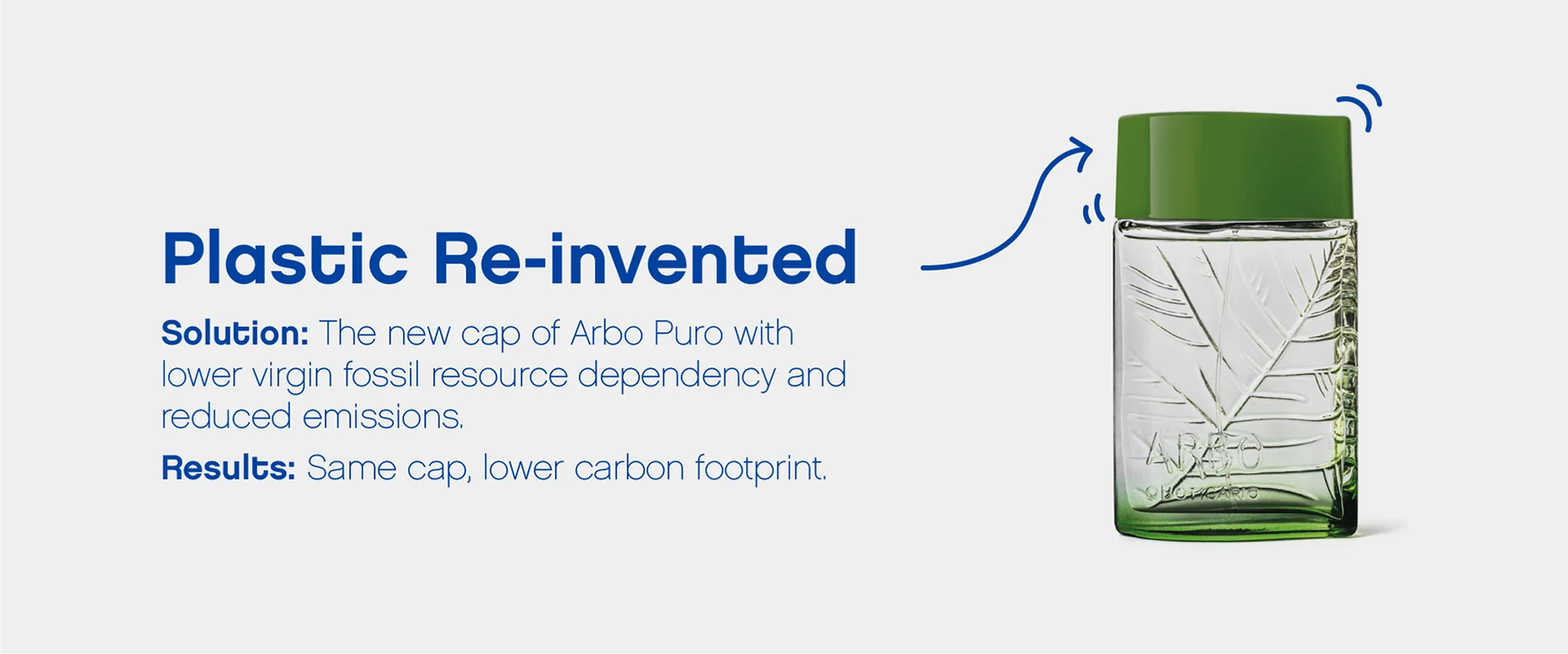

Plastic Re-Invented: Reducing Arbo Puro’s packaging footprint through value chain collaboration

In the transition to sustainable business practices, every action counts. Even small things can make a difference: for example, the cap of a perfume bottle.

Grupo Boticário, a leading Brazilian cosmetics company, demonstrated this through its collaboration with Neste, Borealis, and Aptar. Together, they have innovated more sustainable packaging for the Arbo Puro fragrance line.

The new packaging uses caps made from renewable raw material, which reduces the carbon footprint of the product. This successful partnership showcases how collaborative efforts can drive meaningful progress toward sustainability goals, setting a powerful example for the industry.

An inspiring example

Grupo Boticário is one of Brazil's leading cosmetics companies. Their commitment to the environment goes back a long way. They have been seeking eco-friendly solutions since their inception in 1977.

By 2030, Grupo Boticário plans to use raw materials from renewable or alternative sources for packaging components, such as caps, which are traditionally made from fossil-based plastics. So when Grupo Boticário decided to replace the fossil-based plastic in the caps for their perfume bottles it was totally in line with their commitment to further reduce the environmental impact of its products and packaging.

Sharing a vision - working together

Key to replacing fossil fuels with renewable material is of course that the quality of the end product is not compromised. That is made possible by cooperation between four companies, starting with Neste.

Neste, a leading supplier of renewable diesel, sustainable aviation fuel and renewable raw materials for polymers, provided Neste RE™ to Borealis. Neste RE is a renewable drop-in solution that can be used alone or blended with other materials. Used to replace fossil-based feedstock in plastics value chains, it allows to obtain products of the same high quality.

Borealis, a global provider of advanced and sustainable polyolefin solutions, then processed Neste RE™ into polypropylene that is used in plastic manufacturing. “This project is an excellent example of EverMindsTM in action: customer-centric collaboration among value chain partners that accelerates plastics circularity, and helps lower the carbon footprint of essential packaging components.” says Florin Sabau, Global Commercial Director Consumer Products Flexible at Borealis.

The next partner in the chain is Aptar (AptarGroup, Inc.), a global manufacturer of consumer dispenser packaging. They used the polypropylene to manufacture the bottle caps. “According to our public compromises of sustainability in which we have committed to reaching 100% recyclable, reusable or compostable solutions by 2025, we at Aptar work hard to create solutions that allow plastic circularity while keeping the quality and robustness of packaging. It is gratifying to work with partners who share the same dedication to this goal.” says Pedro Garcia, Product Line Manager, Latin America, Beauty at Aptar.

A small product with a big impact

The new cap of Boticário’s Arbo Puro perfume bottle has equal product properties to its fossil-based counterpart, and is part of Boticário’s sustainable transition.

“We are gratified to have worked with partners who are absolutely aligned with Grupo Boticário’s own environmental agenda. The material solution they were able to provide not only meets our stringent quality standards, but helps us further reduce the environmental impact of our products in a meaningful way.”

Jeroen Verhoeven, Vice President Value Chain Development for renewable polymers and chemicals at Neste, sums it up: “Neste RE™ is our solution for more sustainable plastics. By just changing the source of carbon, and not the product, we can help the industry to make a fast transition from fossil-based feedstocks to those based on renewable and recycled materials with a significantly lower carbon footprint”.