Renewable solutions

6 minute read

Neste’s renewable diesel journey: From visionary beginnings towards a more sustainable future

What began as an innovative idea in the 1990s has grown into a global success story. Lars Peter Lindfors, Senior Vice President, Technology & Innovation at Neste, revisits the key milestones of this journey, reflecting on the pioneering spirit that made it possible and the vision driving Neste into new frontiers.

Neste’s origins as a refining company without its own oil exploration and production operations uniquely positioned it to think differently. “Most big oil companies make their earnings from exploration and production. Neste had to find other ways to generate value, by upgrading low-quality raw materials – mainly crude oil from Russia – to high-quality products,” Lars Peter Lindfors recalls.

As early as in the 1980s, Neste demonstrated this innovative mindset by supplying gasoline components to meet California’s stringent environmental legislation, aimed at reducing tailpipe emissions and improving air quality. These early experiences laid the groundwork for Neste’s later breakthroughs in lower-emission fuel technologies and gave the company vital know-how in navigating regulated fuel markets.

Game-changing NEXBTL technology

The idea that would eventually redefine Neste’s business was born from this same drive for innovation. In the mid-1990s, Neste’s researchers began exploring how to process raw materials from additional streams into hydrocarbons in its fossil refinery, among them tall oil – a forestry by-product. While the patented NEXBTLTM technology wasn’t immediately viable in a fossil fuel context, the introduction of the EU’s biofuel directive in the early 2000s changed everything.

“We realized we had the technology, market knowledge through our fuel station network, and regulatory tailwinds,” Lindfors explains. This was the spark that led to the development of renewable products based on NEXBTL technology, among them renewable diesel, nowadays known as Neste MY Renewable DieselTM, a drop-in solution with which greenhouse gas (GHG) emissions can be reduced by up to 90%* over the fuel’s life cycle when compared to fossil-based diesel. The product, a pure hydrocarbon diesel fuel (hydrotreated vegetable oil, HVO), can be used as a drop-in replacement for fossil diesel. It can be used unblended, i.e. neat (HVO 100) or blended at any ratio.

The path to world-scale production

Lindfors says that Neste’s business model was relatively simple at the start, relying primarily on vegetable oils as the raw material, and then selling the renewable product to a few big oil companies. Nowadays Neste is able to utilize around 10–20 types of renewable raw materials, even poor-quality waste and residues, serving a wide range of customers.

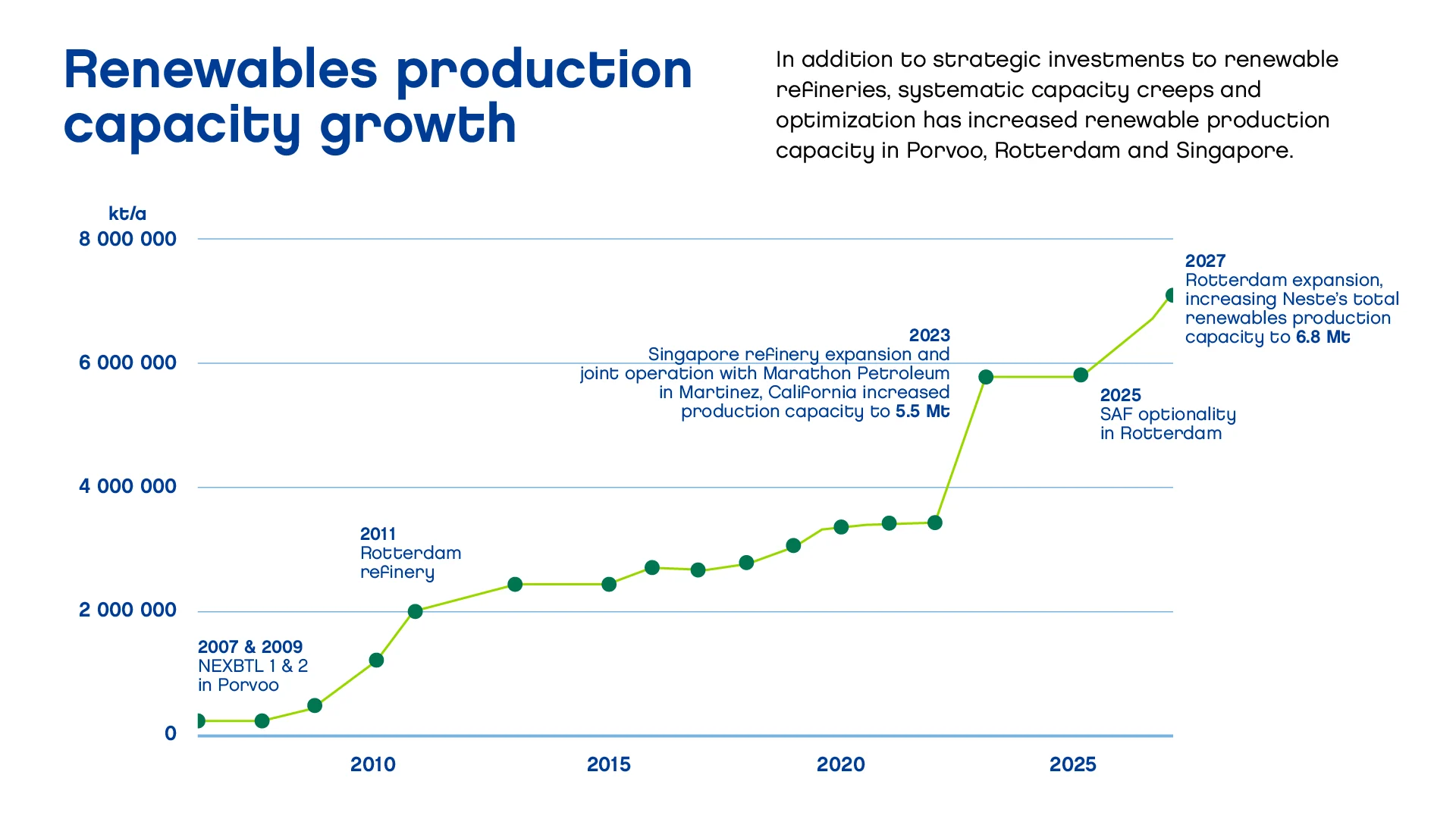

“Because all the hard work to develop NEXBTL refining technology, including sophisticated modeling, was carried out on a laboratory scale first, we were able to avoid extensive scale-up work and move quickly to the industrial level,” Lindfors says. In 2007, Neste inaugurated its first NEXBTL unit at the company’s refinery in Porvoo, Finland.

Lindfors admits that taking the next step and investing in the company’s first world-scale plants in Singapore and Rotterdam in 2010 and 2011 was a bold, high-risk decision at a time when the market was still in its infancy.

“When we started the investments into renewables production, we initially had very few customers in sight.. But you cannot achieve growth and radical transformation without taking risks.”

Thanks to this strategic foresight and continuous innovation, Neste not only survived those early years but built a global value chain. Lindfors points out that today Neste is the world’s leading producer of sustainable aviation fuel (SAF) and renewable diesel. The company has a global reach in raw material sourcing and production on three continents. Neste’s current production capacity of renewables is approximately 5.5 million tons annually. When completed, the Rotterdam refinery expansion project will further increase Neste’s total production capacity of renewable products to 6.8 million tons annually in 2027.

Huge potential in aviation

The market for renewable diesel has largely grown in response to regional or nation-specific regulations and mandates. Demand for renewable diesel grew significantly in the US and parts of Europe because of supporting policies. However, the regulatory landscape has since evolved, introducing new complexities.

“The current saturation of the market is mainly due to incentives for selling renewable fuels decreasing in several countries. In Sweden and Finland, for example, the national obligations for blending and distributing biofuels such as renewable diesel are now much lower,” Lindfors explains, adding, however, that one of the most promising growth areas – and another application for Neste’s refining technology – is sustainable aviation fuel (SAF). With the use of Neste MY Sustainable Aviation FuelTM, GHG emissions can be reduced by up to 80%*) over the fuel’s life cycle compared to using fossil jet fuel. Aviation currently accounts for about 2–3% of global CO₂ emissions, but its share is expected to rise significantly as other sectors decarbonize faster.

“SAF represents a major opportunity. Long-haul flights account for a lion share of aviation sector carbon emissions, and there’s simply no alternative solution for those routes today, as electrification and hydrogen do not work,” Lindfors explains. Renewable hydrocarbons like SAF offer high energy density and seamless compatibility with existing aircraft and fueling infrastructure.

Neste also advocates for balanced, practical regulation that acknowledges the importance of having multiple lower-emission solutions alongside electrification. “No single technology can mitigate climate change alone. Renewable hydrocarbons, such as liquid renewable fuels, will remain crucial, particularly in sectors like aviation and heavy-duty transport,” Lindfors emphasizes.

Expanding the raw material pool and discovering new areas

From fueling city fleets to enabling lower-emission logistics operations and events, Neste’s renewable fuels have proven their versatility and environmental value. But the company isn’t stopping with its current achievements.

“We are continuously broadening our waste and residue feedstock base in the oils and fats, developing our technology value chain, including pretreatment, and improving the production efficiency of renewable diesel and SAF,” Lindfors notes. In addition, the company continues to expand its raw material pool, seeking new lower-carbon-intensity raw materials and investing in a promising technology that enables conversion of lignocellulosic biomass into renewable fuels.

“We are finding new, usable raw materials every year. And we’re actively exploring ways to tap into forestry residues and agricultural by-products. This would create a completely new raw material pool in addition to the current waste and residue streams.”

As new challenges and opportunities emerge – from SAF to global policy shifts – Neste is ready. As Lindfors puts it: “We will become stronger and bigger in the NEXBTL space. And we will still find things to tap into for the future.”

*) The GHG emission reduction achieved with Neste MY Renewable Diesel produced from waste and residue raw materials for the European market (calculation methodology EU RED III (revised RED EU/2018/2001)). GHG emission reduction varies depending on the region-specific legislation that provides the methodology for the calculations and the raw material mix used to manufacture the product for each market.

**) Calculated for neat i.e. unblended sustainable aviation fuel with established life cycle assessment (LCA) methodologies, such as CORSIA methodology.