Textile

4 minute read

A tailor-made collective effort shaping more sustainable polyester

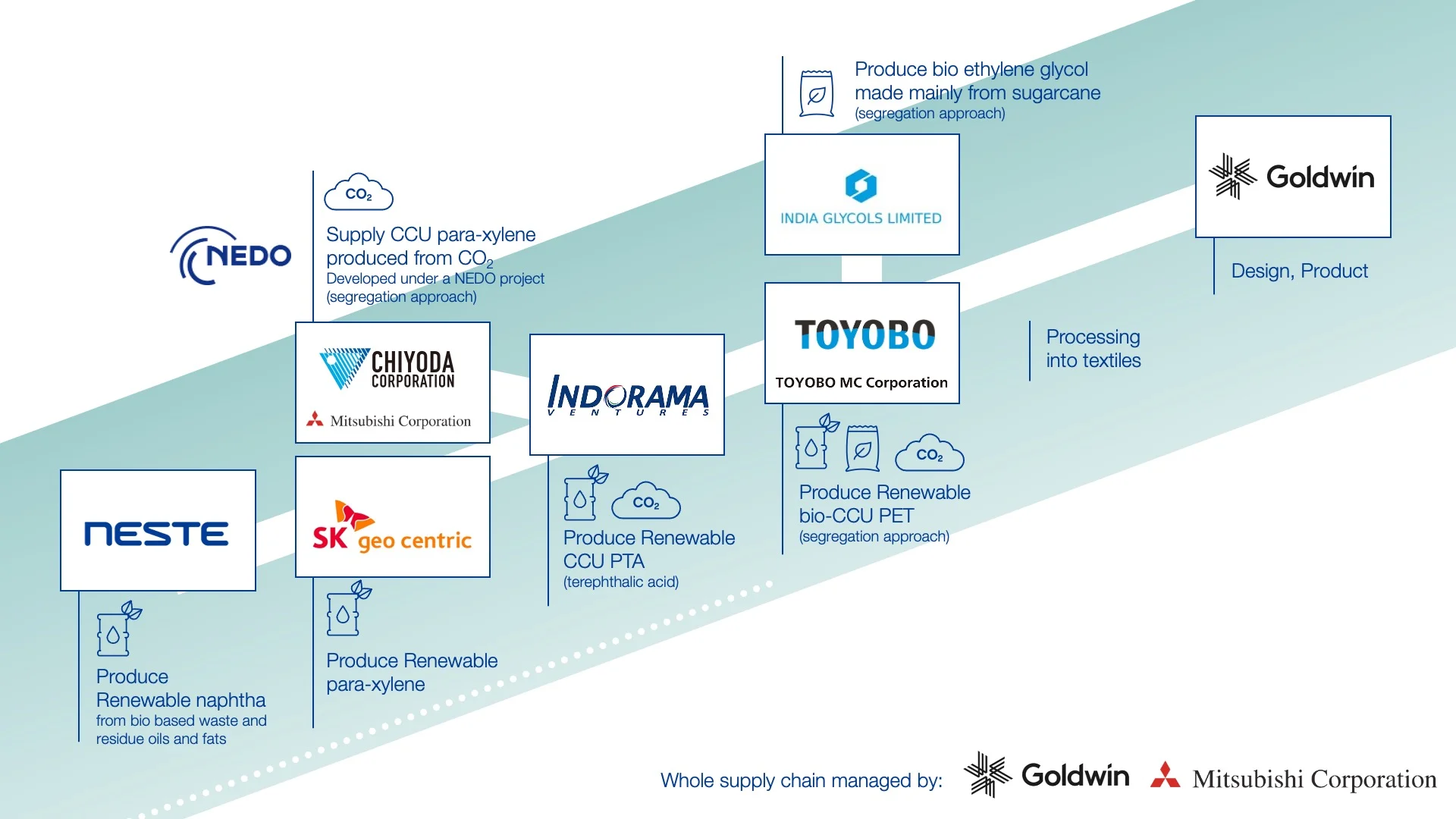

Neste and six companies from across the globe have joined forces to establish the world’s first supply chain dedicated to producing more sustainable polyester fiber from renewable, bio-based, and CO2-derived materials. Led by Goldwin, this collaboration demonstrates how innovation and cooperation can drive the shift toward industry transformation.

In this article:

Discover why polyester's widespread use is a pressing environmental issue.

Explore the innovative collaboration of seven companies led by Goldwin, that’s transforming polyester fiber production.

Learn how Neste plays a crucial role in this pioneering initiative by supplying one of the key raw materials for the collaboration

Polyester – the ubiquitous fiber with a hidden cost

Polyester, a versatile and durable synthetic fiber, has become a staple in the textile industry due to its affordability, strength, and resistance to shrinking and stretching. It is widely used in various applications, from everyday clothing to high-performance sportswear.

However, the widespread use of polyester comes with significant environmental concerns. Traditional polyester, just like most polymers, is derived from fossil resources, specifically crude oil distillates, which contributes to the emission of greenhouse gasses. As the demand for polyester grows, so does the environmental impact, making it crucial to find sustainable alternatives.

Toward a greener future through a collaborative breakthrough

In response to this challenge, a consortium of seven companies across five countries has come together to pioneer more sustainable polyester fiber that minimizes reliance on fossil resources. Led by Goldwin, a prominent Japanese outdoor and athletic apparel company, the consortium includes Mitsubishi Corporation, Chiyoda Corporation (both Japan), SK geo centric (South Korea), Indorama Ventures (Thailand), India Glycols (India) and Neste (Finland).

Together, these players have established a pioneering supply chain that incorporates renewable and bio-based materials, as well as carbon capture and utilization (CCU) technologies in this collaboration.

This innovative polyester fiber is set to be used in The North Face products developed by Goldwin in Japan and South Korea, including sports uniforms by July 2024. The collaboration serves as a model for how industry leaders can unite to drive meaningful change. Goldwin considers expanding the use of it across other brands and products within its portfolio.

Mr. Hikari Mori, COO and Senior Managing Director at Goldwin, emphasizes the importance of this project, stating, "The most significant point is carbon neutrality. Using more environmentally friendly materials was the most important aspect for Goldwin." He further highlights the collaborative effort, noting, "It was also meaningful that many companies were connected as a supply chain, a value chain, or saying from upstream to downstream. Companies were connected from the first raw material to our final product, to do business as one consortium, as one group, which was really impressive for Goldwin."

"In this project, carbon neutrality was our primary focus. Using more environmentally friendly materials has been the most important aspect for Goldwin."

Neste’s role in sustainable polymers

Neste, a key player in the consortium, will supply one of the required ingredients for polymer production. Neste RETM is a renewable feedstock made from bio-based materials such as used cooking oil and waste fats. Neste RE serves as a vital ingredient in the production of the new, more sustainable polyester, offering an alternative to conventional raw materials.

Neste RE is produced through the NEXBTL process that transforms renewable raw materials into high-quality hydrocarbons. Importantly, the use of Neste RE does not require changes to the existing manufacturing infrastructure, making it a seamless and practical solution for companies looking to reduce their environmental impact. The polymers and chemicals derived from Neste RE come with the same quality and performance as those made from traditional fossil-based materials.

According to Christianto Renata, Brand Owner Engagement Manager for the Polymers & Chemicals segment at Neste, "The solutions that Neste is offering for the polymers and chemical industries enable the industries to replace fossil resources with renewable and recycled ones.” Renata continues to state that “the project marks a significant milestone in the sustainable transformation of the polymers and chemicals industry, also for the textile and garment sector."

Ensuring authenticity by tracking the journey

To ensure the traceability and credibility of the materials used, the consortium employs a mass balancing approach. The mass balancing approach is a method used to track and account for materials mixed with conventional feedstocks, allocating the respective proportion to the end product.

The environmental benefits of using Neste RE in polymer production are substantial. An independently reviewed life cycle assessment (LCA) revealed that the use of renewable Neste RE in the polymers and chemicals industry can reduce greenhouse gas emissions over the lifecycle by over 85% compared to conventional fossil-based feedstocks. This significant reduction underscores the potential of renewable materials to transform the sustainability of the textile industry.

A call to action for a sustainable textile industry

The collaboration between Goldwin, Neste, and other consortium members serves as a powerful example of how the textile industry can move towards a more sustainable future. By leveraging innovative materials and working together across the supply chain, these companies are leading by example in reducing the industry’s dependency on virgin fossil resources.

As the world faces increasing environmental challenges, this tailor-made collaborative effort is a call to action for other companies to join forces in innovating for sustainability. By embracing renewable raw materials and pioneering new technologies, the textile industry can play a critical role in building a more sustainable society for future generations.