Plastics

5 minute read

How partnerships are key to directing plastic waste to chemical recycling

Plastic waste pollution is a pressing issue. Novel technologies such as chemical recycling are being developed to get more plastic waste back to circulation and to be used as a resource. Given the abundance of plastic waste, it shouldn’t be too much of a problem to find waste to recycle. But is it really that simple?

Each year, some 350 million tons of plastic waste is generated worldwide. While in industrialized countries the collection of plastic waste may be well established, this is not the case across the globe. Further, even where plastic waste is collected, it may still not be recycled. This means that although there is a lot of plastic waste, directing this waste into recycling is not as easy as the mere amount of it suggests.

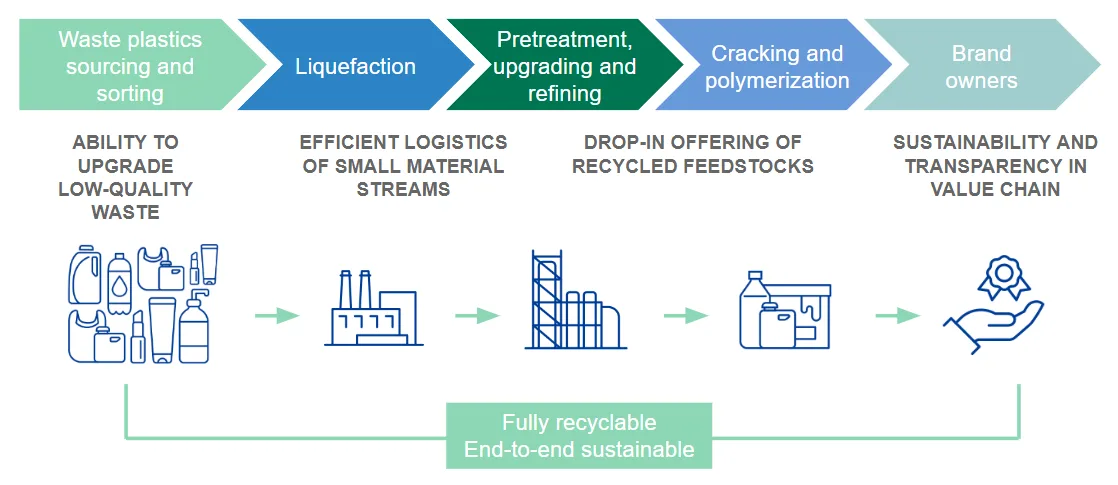

Saana Puumalainen, Head of Supply in Chemical Recycling, and her team are securing the supply of liquefied waste plastic to Neste’s refinery in Porvoo, Finland. Liquefaction through thermochemical technologies, such as pyrolysis or hydrothermal liquefaction, has turned the plastic waste into a material resembling crude oil, which can be further refined by Neste into high quality raw materials for the manufacturing of new plastics.

"To satisfy the demand for liquefied waste plastic, we need to work with multiple partners in the field of liquefaction."

“We are currently seeing liquefaction of plastic waste enter its ramp-up and industrialization phase,” explains Saana Puumalainen. “As of now, we at Neste are also at the beginning of the growth curve, having thus far processed smaller volumes in the range of a few thousand tons of liquefied waste plastic. With our high ambition and ongoing investment projects to scale up chemical recycling, this figure is set to grow fast. To satisfy the demand for liquefied waste plastic, we need to work with multiple partners in the field of liquefaction.”

How do you build a market for something completely new?

Building the supply for liquefied waste plastic and establishing the respective value chains resembles a chicken-and-egg problem to some degree. While Neste is already building capacities to process more liquefied plastic waste in the future, these capacities only pay off if liquefaction capacity is in place. Yet, building liquefaction capacities is appealing only if the demand is in place. So, where to begin?

Neste collaborates closely with technology developers and operators to secure continuous supply. This includes cooperation with well-established companies that are already producing liquefied waste plastics as well as supporting start-ups that are still early in their journey, for instance, when it comes to quality or safety related topics.

“We constantly get positive feedback from our partners both for our capacity to take on challenging waste plastic streams as well as for the support that we can provide,” says Puumalainen. “By working together, we can scale up chemical recycling more efficiently.”

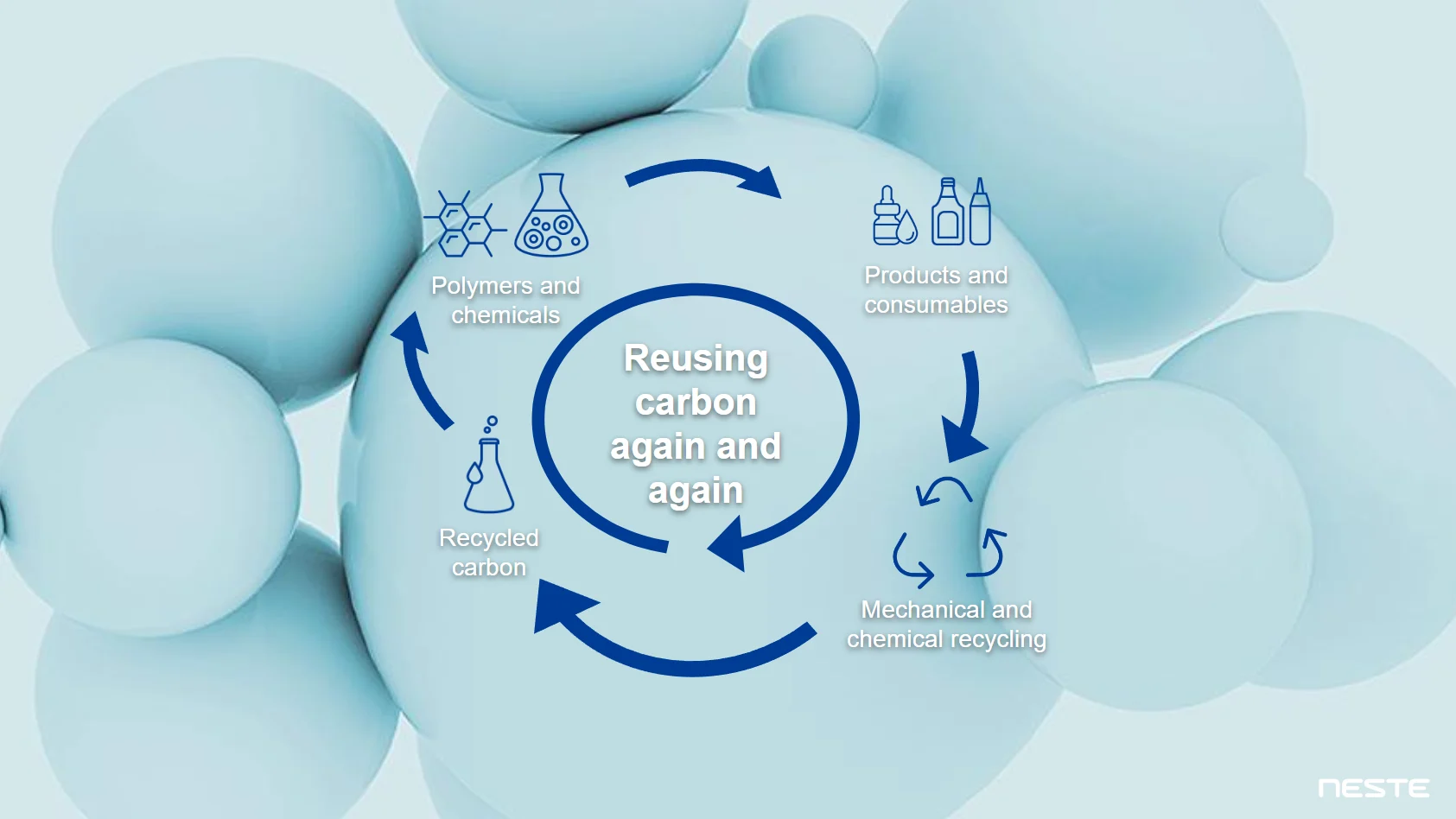

Keeping materials in the loop through recycling reduces the need for virgin fossil resources.

A strong partner for liquefaction companies

Where Saana Puumalainen is looking to secure the supply of liquefied waste plastic, her colleague Outi Teräs, Head of Technology Commercialization in Chemical Recycling, and her team aim to enable the ramp-up of further liquefaction capacity by providing interested partners with robust liquefaction technology.

“Liquefaction technologies, such as pyrolysis, may not be new, but building an industrial scale liquefaction facility that can be operated continuously and reliably with mixed waste plastic streams is not exactly simple,” says Outi Teräs. “We can help prospective partners with the technology, offtake and so much more.”

For most end consumers, plastic waste is plastic waste. In a closer look, the composition of post-consumer plastic waste varies by country, region and even time of year. Plastic waste may contain non-plastic contaminants, such as paper, carton or food leftovers, and include a wide variety of different types of polymers. These impact the liquefaction and subsequent processes.

“Complementarity with mechanical recycling was always the guiding light for us,” explains Teräs. “We needed a technology that can handle varying input without issues. In Alterra, we found a company that was developing just that.”

We can help prospective partners with the technology, offtake and so much more.

Neste’s partner in liquefaction technology, U.S.-based Alterra Energy, started the development of their proprietary pyrolysis process already in 2009 and commissioned an industrial liquefaction plant in Akron, Ohio, in 2016. Neste made a minority investment in the company in 2020, and since then, the two companies have developed the technology together. The joint development has resulted in further improvements in technology efficiency, sustainability and reliability.

“When we started working on our technology, there was not yet a real market for liquefied waste plastic,” says Jeremy DeBenedictis, President at Alterra. “Cooperation with Neste has helped us continuously improve our understanding of the needs of the petrochemical industry, for example when it comes to the quality of the pyrolysis oil. Now our technology can provide a product that fits these needs very well, benefiting all offtakers alike.”

In 2022, Neste acquired the European rights to Alterra’s technology and now licenses the technology in the region.

Chemical recycling turns hard-to-recycle waste plastic into a valuable resource.

Sharing is caring

“To be sure, we have no intention of keeping the technology in Europe to ourselves,” says Outi Teräs. “Quite the contrary, we are hoping to find prospective partners willing to contribute to the circular economy and build liquefaction capacity with us.”

Similarly to Saana Puumalainen’s Supply team, also Outi Teräs’ Technology Commercialization team works to support its prospective partners. Making a liquefaction plant a success is, after all, not just about having reliable technology and customers for the offtake.

“Companies interested in making an entry into chemical recycling struggle with topics like permitting, feedstock choice, site selection and safety. Collaboration with Neste can help scale up capacities faster and de-risk the investment," Outi Teräs explains.