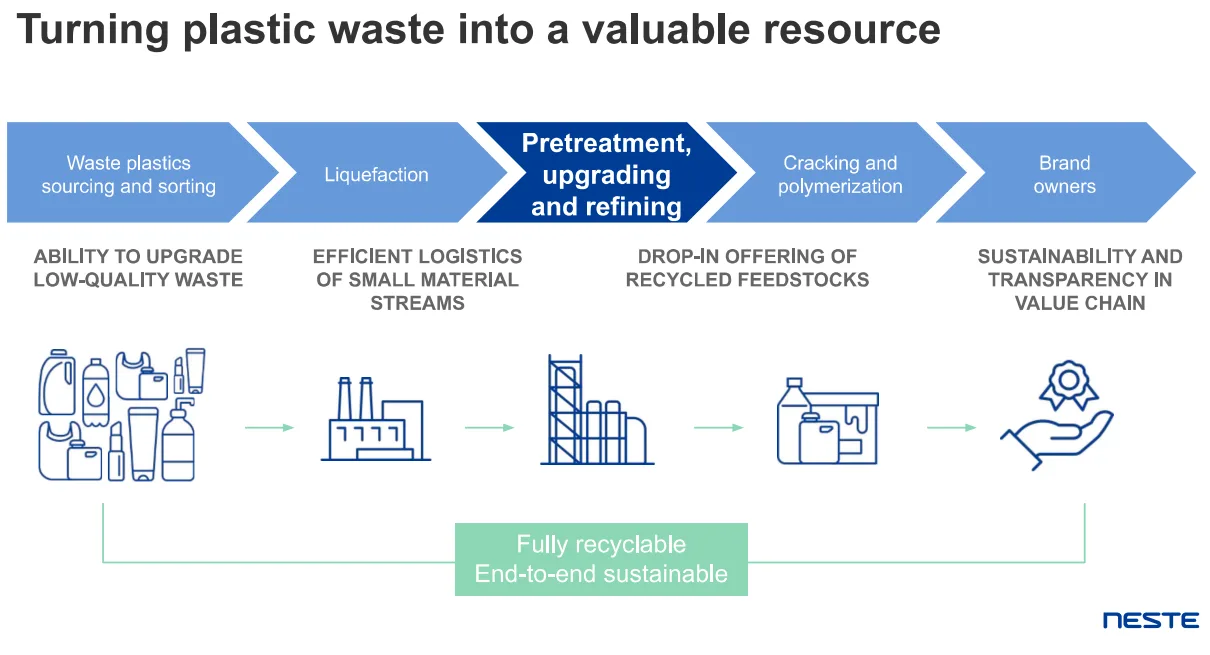

Neste started refining liquefied waste plastic on an industrial scale in 2020, and has since processed increasing volumes in several runs. While unprocessed liquefied waste plastic is feasible in limited campaign runs, scaling up continuous processing will require the upgrading step to remove impurities and optimize the chemical composition.

In June 2023, Neste made a final investment decision to commence construction of upgrading facilities in Porvoo in the course of project PULSE. With the investment of 111 million euros, Neste will build the capacity to upgrade 150,000 tons of liquefied waste plastic per year. The new facility is planned to be finalized in 2025.

Project PULSE*, which would have received an EU Innovation Fund grant of 135 million euros if fully implemented, originally included the building of a pretreatment unit for which Neste has decided to reevaluate an investment decision at a later point in time. *) Views and opinions expressed are those of the author(s) only and do not necessarily reflect those of the European Union or European Climate Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.